+ 381 64 144 69 55 branislavkozenko@gmail.com Address: Savska 18, 22426 Jarak, Serbia

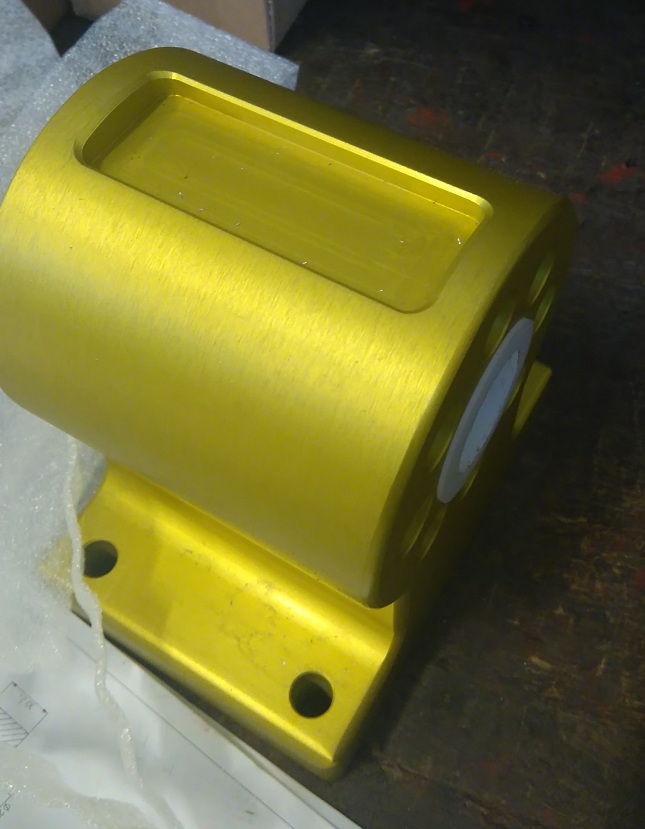

Anodizing (electrolytic oxidization) is the process of using electrical current to the cases of aluminum and its alloys produced by the layer of aluminum oxide. Anodized layer protects the object from corrosion and wear, serves as electrical and thermal insulator, and can serve as a base for spreading protective paints and varnishes. The process of anodization comprises: - Mechanical brushing prepares profiles, devices with circular brushes of thin stainless steel wire - Degreasing in detergents at a temperature of from 65 to 75 ° C for 10 minutes - Degreasing in mineral drums (sodium hydroxide) at a temperature of 40 to 60 ° C for 5 minutes - Neutralization of the nitric acid - Anodising in sulfuric acid at a temperature of 18 ° C for 50 minutes - Coloring (if required other hue) - Closing the pores or alloying (cold and hot), about 3 minutes. In addition to the standard aluminum anodizing services, we can deliver the service hard anodization. Also, in cooperation with our company you can obtain the highest quality paint for anodizing.